New cooling and air conditioning systems

The Laboratory of Applied Thermodynamic and Refrigeration Technology of Refrigerated Vehicles of the School of Mechanical Engineering has developed in collaboration with the Greek and international industry a series of laboratory devices for the research and application of energy systems. These systems focus on power generation and cooling with low-environmental impact systems.

Among the provisions are Heat Pumps of alternative refrigerants, such as propane R290. This natural refrigerant offers high energy efficiency and has a low global warming potential, making it an environmentally friendly choice.

In addition, a CO2 Chiller device has been installed which uses carbon dioxide as a refrigerant, providing an efficient and ecologically responsible solution for industrial cooling. This technology finds applications in food preservation and freezing systems, offering high efficiency in terms of refrigeration and energy efficiency.

The liquid dehumidifier is another innovative solution, using a non-adiabatic dehumidifier with a plate heat exchanger to transfer heat and reduce air humidity. This system is ideal for spaces where humidity regulation is vital without the use of a compressor.

Finally, the solar cooling device with adsorption chiller and solar cogeneration system integrates solar panels to generate thermal energy as well as PCMs to store this heat. The stored thermal energy is used to cool through the adsorption chiller, reducing energy requirements and efficiently utilizing solar energy.

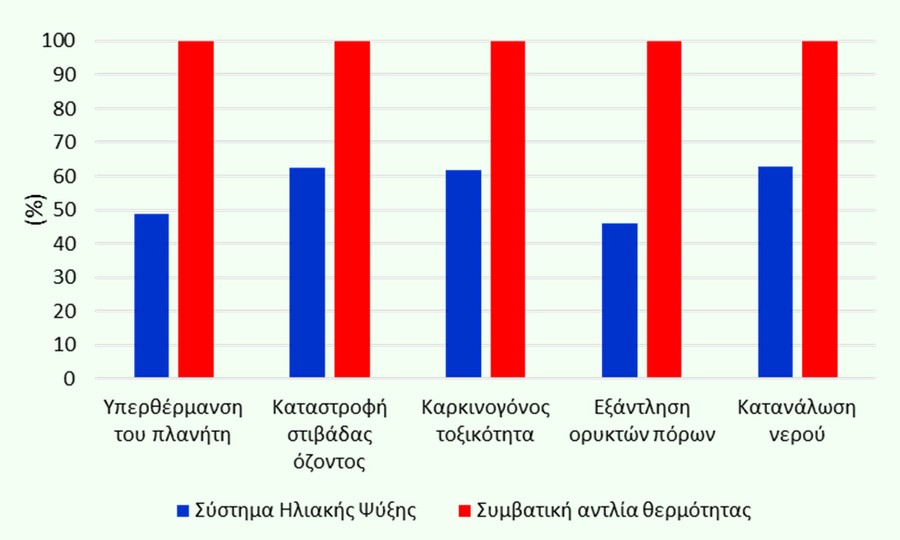

Of a similar nature, is the upgrade of the Steam Engines and Boilers Laboratory of the School of Mechanical Engineering with the integration of a solar cooling-heating system to fully cover the thermal and cooling needs of five offices of the laboratory. The solar cooling-heating system is based on the integration of a solar cooling/heating system consisting of a 12.5 kW adsorption cooler and a 30.0 kW auxiliary heat pump, which have been installed in the Steam Engines and Boilers Laboratory of the National Technical University of Athens. The heat generated in the adsorption chiller comes from a solar vacuum collector field with a total area of approx. 40 m². Emphasis was placed in the design of the system on minimizing the environmental footprint of the system, through its life cycle analysis and comparison with a conventional commercial heat pump.

(a)

(b)

(c)

Fig. 16. (a), (b) Illustration of the solar cooling system and (c) indicative results of the comparison of the environmental footprint